|

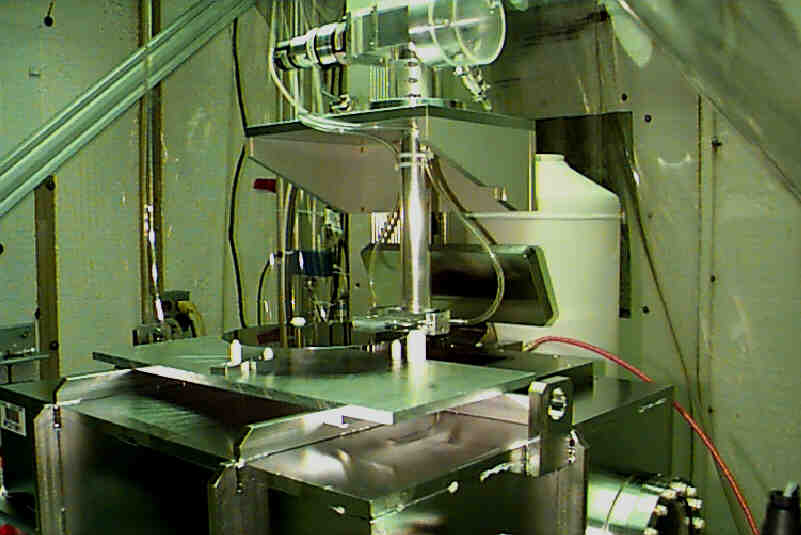

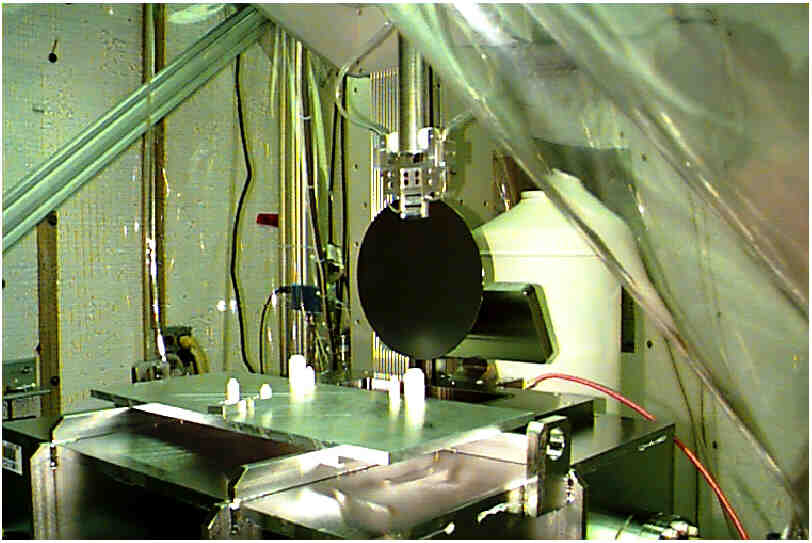

| | Shown below is the wafer loading sequence into the TXRF chamber.

This chamber has been placed in a cleanroom to prevent contamination while

measuring the wafer. Seen in the pictures below are the chamber (center

bottom), the SiLi detector (left), and the wafer loading robot (top,

middle).

|

Initially, the wafer is placed on top of the chamber on Teflon plugs by

a human, with the wafer backside up.

|

|

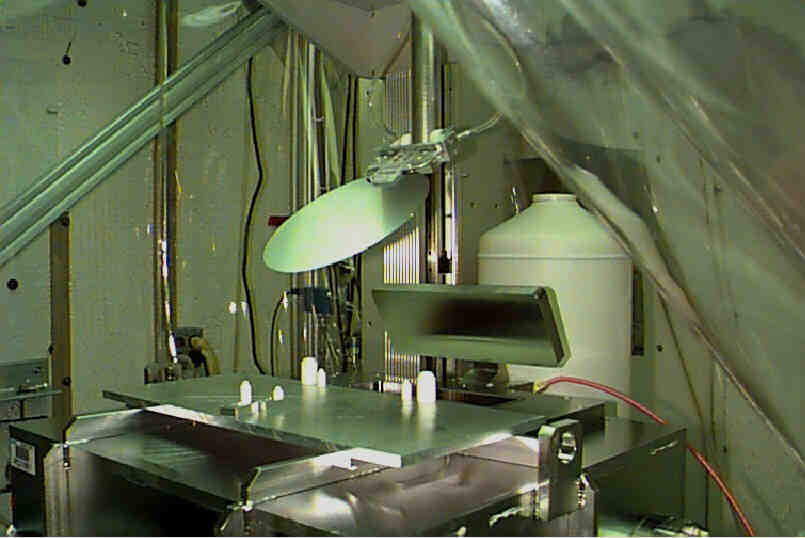

The motorized robot then descends towards the wafer, and establishes

contact with the wafer.

|

|

By using a vacuum wand, the robot maintains its "grip" on the

wafer as it slowly raises it.

|

|

After reaching a predetermined height, the robot then rotates the wafer

90 degrees for entry into the TXRF chamber.

|

|

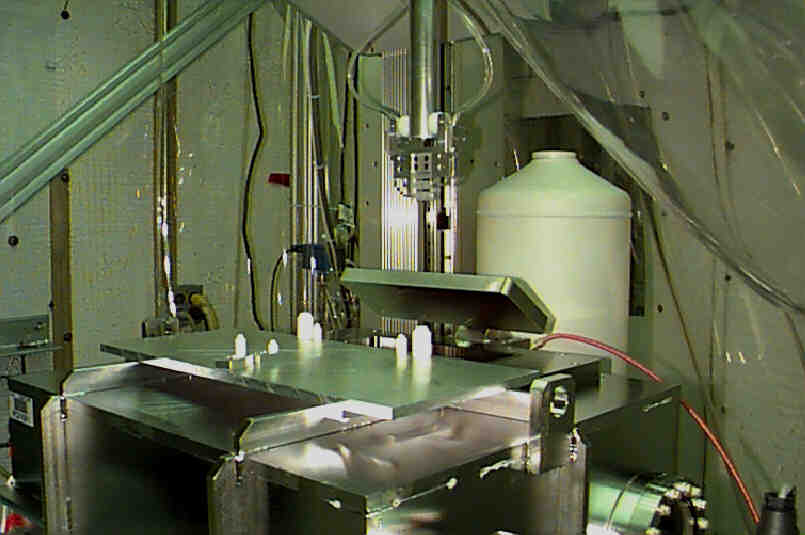

Upon completion of the rotation, the robot then lowers the wafer slowly

into the chamber.

|

|

Inside the chamber, an electrostatic chuck exists,

however, this chuck can only be used in near vacuum conditions.

|

|

After leaving the wafer inside the chamber, the robot

arm moves up and out of the way.

|

|

Finally, the chamber door is closed and the can now be

pumped down. After pumping, the electrostatic chuck is turned on

and provide the force to hold the wafer upright.

|

|

Lower part of TXRF vacuum chamber. Seen on side of chamber are

electrical inputs to hold the wafer on the chuck and move the wafer to

various positions in the X-Ray beam, connections to vacuum pumps, and

a viewing port to allow visual check of the wafer position.

|

|